|

Dri-Seal Jiffi-Plug

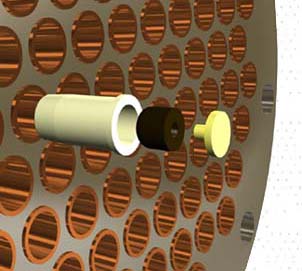

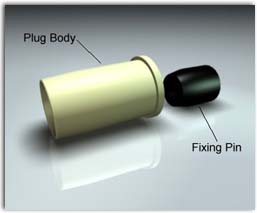

The Dri-Seal Jiffi-Plug offers a new and inexpensive way to seal leaking heat exchanger tubes safely, and with the minimum of fuss. The two components that make up the Jiffi-Plug (main body and a nickel plated expansion pin) are all produced from advanced polymer materials. This combination of materials together with the unique design of the products results in the ability to withstand temperatures of up to 150° C and working pressures of up to 300psig. The Dri-Seal Jiffi-Plug offers a new and inexpensive way to seal leaking heat exchanger tubes safely, and with the minimum of fuss. The two components that make up the Jiffi-Plug (main body and a nickel plated expansion pin) are all produced from advanced polymer materials. This combination of materials together with the unique design of the products results in the ability to withstand temperatures of up to 150° C and working pressures of up to 300psig.

How Does It Work?

The external dimensions of the plug body are designed to be an interference fit in the tube end. The internal profile incorporates two main attributes:-

1) The domed internal face is designed to displace the stresses resulting from internal tube pressure towards the plug periphery, thus increasing radial expansion into the tube bore and counteracting a force which could dislodge the plug from its position.

2) The tapered internal bore of the plug, combined with the parallel diameter of the fixing pin, results in a flexible and consistent circumferential expansion into the tube bore.

This unique design ensures that any increase in pressure within the channel resulting from the operation of the heat exchanger can only drive the expansion pin further in, once again resulting in an improved seal with the tube bore. The specific materials used for the plug body and expansion pin can be tailored to suit the particular environmental conditions of the host heat exchanger. The particular grades of polymer which have been chosen as standard are suitable for a wide range of mediums including fresh water, seawater, oil, freon and many other chemicals and solvents. This unique design ensures that any increase in pressure within the channel resulting from the operation of the heat exchanger can only drive the expansion pin further in, once again resulting in an improved seal with the tube bore. The specific materials used for the plug body and expansion pin can be tailored to suit the particular environmental conditions of the host heat exchanger. The particular grades of polymer which have been chosen as standard are suitable for a wide range of mediums including fresh water, seawater, oil, freon and many other chemicals and solvents.

|